This overload safety is also possible for 10, 40, 100 or 400 bar (145, 580.2, 1,450.4 psi) special designs.

#400 BARS TO PSI FULL#

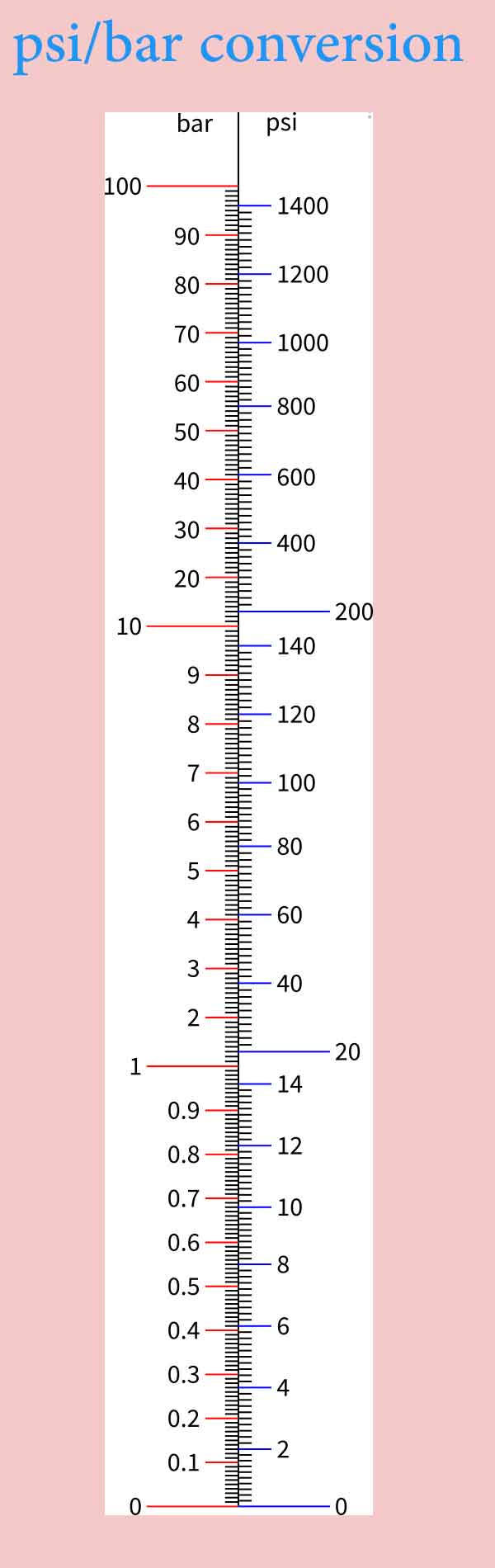

Depending on the instrument model and pressure range, an overload safety of 3x or 5x the full scale value is standard. Pressure gauges with open connecting flanges are even suitable for highly viscous and contaminated media, in aggressive environments too. These pressure gauges with diaphragm pressure elements are suited to gaseous and liquid, aggressive media. Why do gauge pressure gauges with diaphragm element are used for high overload safety (16 mbar … 40 bar / 0.2. 400 Psi to Bar to convert 400 Psi to Bar and vice versa. A DKD/DAkkS certificate can be generated for these pressure gauges. psi into barConvert 0.7 Pounds per Square Inch (psi) to Bars (bar). When it comes to the highest accuracy, within WIKA's broad selection you will also find precision pressure gauges measuring with accuracies of 0.1, 0.25 or 0.6 % of the full scale value. Liquid filling of the case ensures precise readability for the pressure gauge, even with high dynamic pressure loads and vibrations. For measuring tasks in aggressive, not highly viscous and non-crystallising media, even in aggressive environments, the stainless steel variants are suitable. The area of application for these pressure gauges with Bourdon tubes is liquid and gaseous media. Why are gauge pressure gauges with Bourdon tube used for relative pressure (0.6 … 7,000 bar / 8.7.

#400 BARS TO PSI FREE#

For pressure gauges with a free zero point, the accuracy class applies from 0 to 100 % of the scale range.

For pressure gauges with a pointer stop, the accuracy class applies from 10 to 100 % of the scale range. The accuracy class specifies the permissible deviation of the indication in percent of the full scale value. As nominal sizes (NS) the following are specified for pressure measuring instruments: NS 40, 50, 63, 80, 100, 160 and 250. The scale ranges are standardised by EN 837 and the preferred pressure unit is the bar. In addition to decisive factors such as the type of pressure to be measured, the scale range, nominal size (NS, case diameter) and accuracy class of a pressure gauge also determine the version of the scale. Flanges made in different materials show different pressure. Flanges with a higher rating (class) are stronger than flanges with lower ratings, as they bear more pressure at increasing temperatures. What must be taken into account when selecting the right pressure gauge? The term flange rating (or class) refers to the maximum pressure (in psi or bars) that a flange withstands at increasing temperatures. Laboratory analysis of SF 6 & alternative gases.Basic materials (minerals, metals, paper).Valves with integrated pressure regulators.Heat transfer and distribution stations.Laboratory analysis of SF6 and alternative gases.International service network with system calibration.Power transmission and distribution (SF 6).Precision pressure measuring instruments.The gauges can operate at temperature -20☌ to + 60☌.Ī calibration certificate is not available. Make sure that your medium is compatible with brass. The gauges are made of plastic or steel, the window material is made of polycarbonat, the connection has a thread size of G 1/8 inch or G 1/4 inch and is made of brass. Scale division ranges from 0.02 to 50 bar.

#400 BARS TO PSI SERIES#

The measurement range for the gauges of this series is from -1 to 400 bar. The gauge diameter is 40, 50 or 63 mm, the accuracy class 1.6 for steel housing and 2.5 for plastic housing. The MW Series pressure gauges are available with a vertical or horizontal type connection.

The gauge body is made of plastic, the connection and indicator are made of brass. The measurement accuracy class is 2.5 (± 2.5 % maximum deviation). The gauge has two measurement scales in bar (black) with scale division of 0.5 and in psi (red). The pressure gauge MW01040PV-18 is designed for gas and liquid media and measures pressures within the range of 0 to 10 bar (0.145 psi).

0 kommentar(er)

0 kommentar(er)